1. Can provide efficient gas compression, thereby improving energy utilization in industrial processes. Advanced air compressor technology also has energy-saving functions, reducing energy waste through optimized operation.

2. Maintain efficient operation over a long period of time. 1. It has automatic monitoring and maintenance functions to ensure the reliability and stability of the equipment.

3. Adopt low-noise design to improve the working environment by reducing the noise level during operation.

4. Pay attention to environmental protection and use advanced technology to reduce energy consumption and reduce environmental impact.

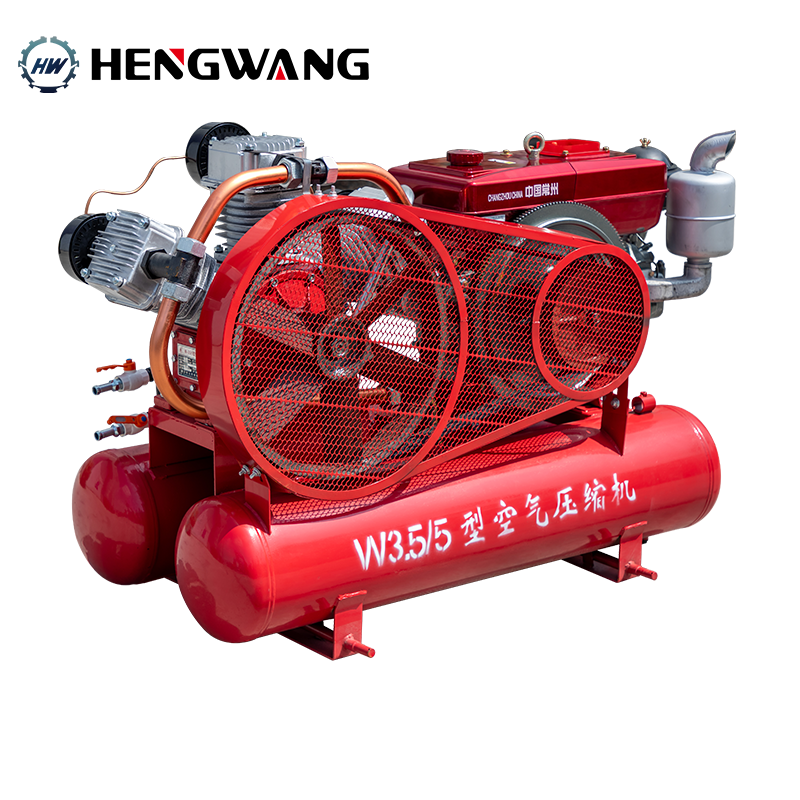

| model | Supporting diesel/electric power | Cylinder number cylinder diameterpcs x mm | Rated speed r/min |

| W-1.8/5 | S1100*11kw | 3*Φ100 | 1200 |

| W-2.8/5 | S1110*15kw | 3*Φ115 | 1120 |

| W-3.0/5 | S1115*18.5kw | 3*Φ120 | 1070 |

| W-3.5/5 | S1115*18.5kw | 3*Φ125 | 1170 |

| W-3.2/7 | S1125*22kw | 3*Φ125 | 980 |

| SF-4.0/5 | S1125*22kw | 4*Φ120 | 1070 |

| 2V-4.0/5 | S1125*22kw | 4*Φ120 | 980 |

| Rated exhaust volume M3/min | pressure Mpa(Kg/cm²) | Overall dimensions L*W*H m | weight |

| 1.8 | 0.5(5) | 1500*600*950 | 300 |

| 2.8 | 0.5(5) | 1670*820*1150 | 450 |

| 3 | 0.5(5) | 1880*870*1230 | 460 |

| 3.5 | 0.5(5) | 1880*870*1240 | 460 |

| 3.2 | 0.7(7) | 1820*740*1520 | 480 |

| 4 | 0.5(5) | 1960*860*1300 | 655 |

| 4 | 0.5(5) | 1800*950*1300 | 750 |