Core Technical Advantages

1. Optimized Speed Ranges & Torque Profiles

Multi-stage RPM Control:

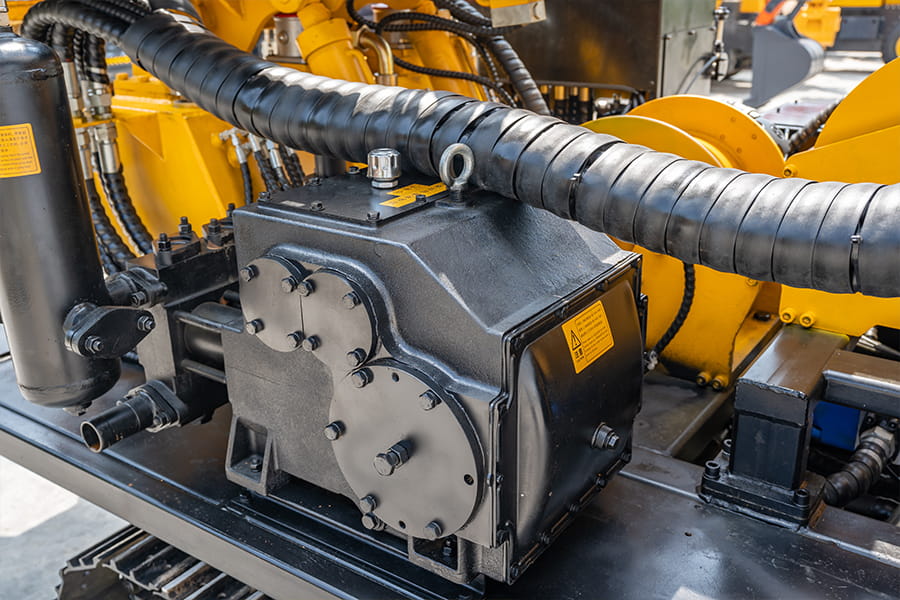

8-speed transmission delivers 83–970 RPM (forward) and 67–206 RPM (reverse), enabling precise adjustments for diamond drilling in granite or shale.

Hydraulic-driven systems sustain 4,200 N·m torque at 1,300 RPM, minimizing tool slippage in abrasive strata.

Low-Speed High-Torque Mode:

350–800 RPM range with 3,500 N·m torque maximizes efficiency in small-diameter (46–93 mm) core sampling.

2. Modular Mobility & Maintenance-Friendly Design

Dismantles into ≤300 kg modules for transport via pack animals or light trucks in mountainous terrain.

Open-frame architecture simplifies component access, reducing maintenance downtime by 40%.

3. Operational Stability & Safety

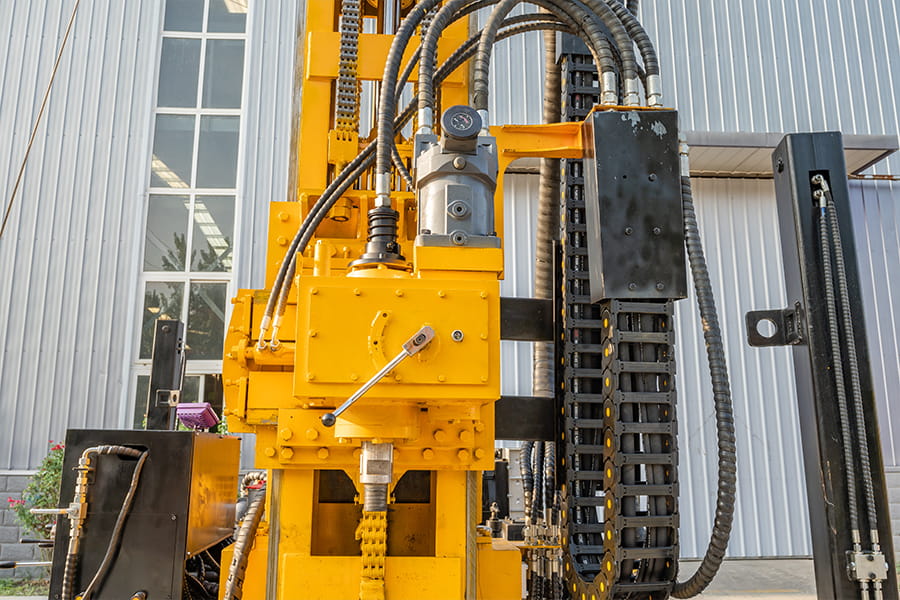

Dual Reverse Speeds: Enables swift rod extraction during jamming incidents without manual tower adjustments.

Reinforced Steel Chassis: Reduces vibration to <0.3 mm amplitude at 900 RPM for stable high-speed drilling.

4. Intelligent Control Systems

Real-Time Monitoring:

In-cabin displays track drilling pressure (0–22 MPa), RPM deviations (±5%), and torque fluctuations.

Auto-Feed Mechanism:

Hydraulic feed maintains constant WOB (50–120 kN) during rod changes, boosting productivity by 25%.

Deployment Scenarios

Geotechnical Drilling Rig: Slope stabilization surveys via 75° inclined boreholes in landslide zones.

Exploration Core Drilling Rig: High-density sampling (1,500 m max depth) for rare earth mineral mapping.

Geological Exploration Drilling Rig: Subaqueous drilling (≤30 m depth) with sealed bearing assemblies.

Geotechnical Drilling Rig: Multi-angle adaptability for unstable terrains.

Exploration Core Drilling Rig: High RPM-torque synergy for hard rock.

Geological Exploration Drilling Rig: Modular mobility for remote operations.